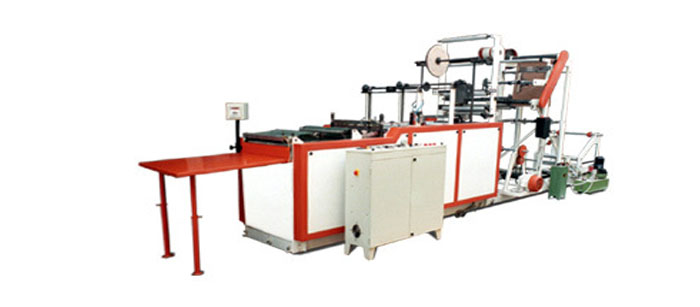

Double Line Model No: TRJV-2SS-350+350/R500+500/600+600

The side seal bag making machine delivers 50 to 350 strokes / minute Depend on Model and is suitable for LDPE / HDPE / PP / BOPP films. There are a various attachments available for this machine to make a variety of bags like handle punch, pre sealer, bottom gusset, inside / outside lip former, perforation, tape applicator for courier bags, web aligner etc.

Technical Specifications

- Electrical power - AC, 3 ph, 415 +- 6 %, 50 Hz (Specific your Supply)

- Maximum Stroke/minute - (50 to 250)*2-Lines bags per minute=100 to 500 bags per minute, Maximum line speed - 30 to 65 meter/minute on each line, Min to Max Gauge - 20 to 87 micron (60 to 350 gauges). Like Recommendation for LD, LLDPE-32 to 85 / PP,CPP, PE, BOPP-20 to 80 /HDPE -20 to 75, Machine Weight and Dimension is base on attachments include and model selected (* Depend upon model and gauge material & length of bag and operator skill for work.).

- Servomotor & Driver with PLC com MMI.

- Photocell unit for printing bags.

- Control penal system along with SSR and Push buttons.

- M. S and Cast iron fabricated modular structure Design.

- Efficient Digital temperature controller & counter.

- High quality efficient conveying system.

- A/C Frequency controlled Drives.

- In put protective M C B's and Proximity sensor.

- Center and side slitting attachment will be provided.

- Digital batch counting meter with & pre set wish ling (Inbuilt in MMI).

- Static charge remover with their electrodes.

Attachments

- Edge Guiding system (EPC)

- Ultrasonic Seal Attachment with Pearl Insert / Ultrasonic Knurling

- "V" Cut Attachment (Cold Cut)

- Film Folding Device (V-Triangle Frame).

- Strip Insertion.

- Carry Handle Punch (Loop and Patch Type)

- Bottom Gusseting and Lip Formations + Lip Sealing.

- Chicken bag Assembly

- Punches Like Hanger (Euro Hole), Pin Hole, Wicket Hole, Round Hole, D-cut Punch,

- Necessary Pneumatics for punches, 2ed seal etc.

- Air Dryer and Filtering system for Pneumatics.

- Any Specific Attachment.

+91 98256 03210

+91 98256 03210